Introduction

- India’s strengths have already been defined in traditional textiles and natural fibres globally.

- It is the second largest producer of polyester in the world and is now emerging as a key player in technical textiles industry contributing to a market size of $ 19 Bn.

- Technical textiles is a fast-growing sub-segment that finds its usage in an array of sectors.

- The end use application of technical textiles is widespread and seen in industries such as agriculture, construction, sports apparel, healthcare etc.

- India’s leap towards modernisation and its manufacturing competitiveness are some of the key contributors to the growth of this segment.

- This report elaborates the current scenario of technical textiles and highlights ways to tap into India’s growth potential in this sunrise sector.

What are Technical Textiles?

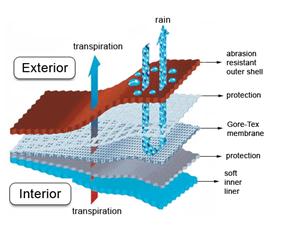

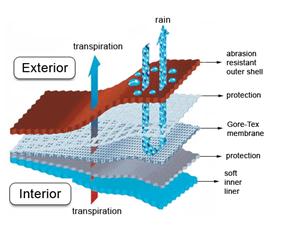

- Technical textiles are defined as textile materials and products which are manufactured primarily for their technical performance and functional properties rather than aesthetic and decorative characteristics.

- These textiles are manufactured mainly from synthetic fibres and are usually nonwoven textile products. However, these can be woven or non-woven and combinations of both.

- This type of textile can be made up as a single or multiple-layer and can be produced as a composite or a coated and/or impregnated material.

- These can be made from any fibre yarn or filament of purely natural or synthetic origin or combination of the two types.

Textile Sector: Prospects of growth in India

- The Indian Textiles Industry has an overwhelming contribution in India’s economic growth.

- It contributes about 14 percent to industrial production, 4 percent to the country’s gross domestic product (GDP) and 17 percent to export earnings.

- It is the second largest provider of employment after agriculture as it provides direct employment to over 35 million people.

- Adequate availability of raw materials such as cotton, wool, silk and jute and skilled workforce has contributed largely in the expansion of this sector.

- Technical Textile

- The advent of Man-made fibers (MMF) coupled with technical expertise has provided for the growth of the technical textile sector in India.

Global Growth Forecast

- The technical textiles global market is expected to grow from USD 177 billion in 2018 to reach USD 220 billion by 2022.

- Largest producers: the United States of America is the world's largest producer and consumer of technical textiles having 23% share followed by Western Europe having 22 % share, China having 13%, and Japan having 7% share.

- In Asia, China is a market leader while Korea, Japan, India, and Taiwan are the other key players of technical textiles.

- India’s share: The share of India in the world technical textiles market is about 4-5%.

- The exports of technical textiles from India stand at Rs 14,013 crore in the year 2018-19 and it is expected that it will reach a level of Rs 20,000 crore in the next two years.

- The technical Textile sector in India is expected to grow at the rate of 12% per annum, with the government’s aim to achieve 20% annual growth.

|

Applications of technical textiles

- Technical textile products are manufactured mainly using specialty fibers such as Nomex, Kevlar, Spandex, Glass, and Carbon, etc.

- These fibers exhibit enhanced functional properties like higher tenacity, excellent insulation, improved thermal resistance and chemical resistance, etc.

- Technical textiles are used in different forms in various industries like construction, transport, agriculture, medical, hygiene, and sporting.

Fig: Technical Textiles

Medical protective gears

- Amid the COVID-19 pandemic, India became one of the largest suppliers of technical textile products such as gloves, medical suits, and masks e.t.c.

- Bandages and sutures which are used for stitching wounds are types of technical textiles.

- Hollow synthetic fibers are used with nano-particles for the delivery of drugs to any specific part of the body. Cotton, silk, PES, and polyamide fabrics are also types of technical textiles that are used in medical applications.

Industrial usage

- Technical textiles are used for filters, machine clothing, conveyor belts, and abrasive substrates in industries.

- These textiles are also used in industrial products such as electrical components and cables, flexible seals and diaphragms, and acoustic and thermal insulation for other domestic appliances.

- Various types of woven, knitted, braided, nonwoven, and wound yarn reinforcements made from glass, carbon fiber, and organic polymer materials such as aramids fall under the ambit of technical textiles.

Sports and lifestyle accessories

- Technical textiles are composed of materials that are tougher than wood, having the passage of air, waterproof like rubber, and are eco-friendly and highly economical.

- The technical textiles which are used for sports and lifestyle accessories are termed as

- These textiles combine utilitarian functions with wearing comfort that leads to achieving a high level of performance.

Transport: Technical textiles that are used in the automotive or transport sector are termed as “MOBILTECH.”

- Aircraft, shipbuilding, motor vehicle, and train manufacturers use this type of textile largely.

- Mobiltech covers safety aspects as well as comfort and style to provide aesthetically pleasing interiors, great comfort, and fuel economy.

- It consists of visible components like upholstery, carpets, seat belts, headliners as well as concealed components like tyre cords, hoses, belts, airbags, etc.

Used for making protective gears: Technical protective fabrics that are used or making different types of protective gears are called ‘PROTECH’.

- These fabrics are used for making personal protective gears used for worker’s safety in different types of works.

Agriculture: The technical textiles which are used in agriculture are called ‘AGRITECH’. These textiles are used for crop protection and fertilization.

- The properties of these textiles are strength, elongation, stiffness, bio-degradation, resistance to sunlight, and resistance to a toxic environment.

- They help in preventing erosion and paves the way for afforestation in greenhouse cover and fishing nets.

- They are used for layer separation in fields, nets for plants, rootless plants, and protecting grassy areas as well as for sunscreens and windshields.

Construction: Technical textiles that are used in the construction sector are termed as ‘Buildtech’.

- These textiles are used in concrete reinforcement, façade foundation systems, interior construction, insulations, roofing materials, air conditioning, noise prevention, visual protection, protection against the sun, and building safety.

- PVC coated high tenacity polyester (PES), Teflon coated glass fibre fabrics and silicone coated PES are common types of technical textiles that are being used.

Clothing: Shoelaces, interlinings, zip fasteners, elastic narrow fabrics (tapes), Velcro, labels, umbrella cloth, and sewing threads are made by technical textiles. These are called ‘Clothtech’.

Technical textiles used for environment protection: These textiles are called ‘ecotech’ and are used in applications such as floor sealants, erosion protection, air cleaning, prevention of water pollution, water cleaning, waste treatment/recycling, depositing area construction, product extraction, and domestic water sewerage plant.

- It refers to the use of geosynthetic products to secure landfills against leakage of municipal or hazardous waste.

Heat and flame protective clothing: Technical textiles are currently being used for Heat and flame protective clothing.

- It is being used for prolonged protection where the wearer is subject to severe radiant and convective heat or to direct flames, such as the firefighter’s suit.

Government Initiatives to Boost Technical Textiles Market

- National Technical Textiles Mission

Nodal Agency: Ministry of Textiles

- It aims to provide impetus to the technical textile sector and make India a global leader in this sector.

- Increasing Market Size: It aims to promote technical textiles in the domestic economy and increase its market size up to $50 billion by 2024.

- Dedicated fund for the development of technical textiles: It aims to focus on research, development, and innovation in the field of technical textile with an outlay of ?1,000 crores.

- The fund will be dedicated to research and development at the fibre level as well as application-based in geo, agro, medical, sports, and mobile textiles as well as the development of bio-degradable technical textiles.

- Apart from Research and Development, the fund also aims to provide impetus to the development of machinery and process equipment for the production of technical textiles in India.

- Promotion and Marketing: The mission also aims to promote and development of the market for technical textiles so that they must be absorbed into the mainstream economy.

- Promotion of export: The mission also aims to promote the export of technical textile so that it can increase from ?14,000 crores to ?20,000 crores by 2021-2022.

- The mission aims to ensure 10% average growth every year and set up an export promotion council.

- Human Resource Development: The mission aims to provide training, education, and skill development to develop skilled human resources.

- It aims to promote technical education in the field of technical textiles at higher engineering and technology institutions to provide better-skilled human resources in this sector.

Technotex India

- It is a flagship event organised by the Ministry of Textiles, in collaboration with Federation of Indian Chambers of Commerce & Industry (FICCI) and comprises exhibitions, conferences and seminars with the participation of stakeholders from across the global technical textile value chain.

Schemes

- Scheme for Integrated Textile Park (SITP): To boost entrepreneurship by providing financial support and state-of-the-art infrastructure, the scheme was launched in 2005 and has recently been extended for the period between 2017-20.

- Technology Mission on Technical Textiles (TMTT): Centres of Excellence Ministry of Textiles had launched Technology Mission on Technical Textiles (TMTT) with two mini-missions for five years from 2010-15 which entailed the creation of the following eight Centres of Excellence to provide infrastructure support, lead research and conduct tests of various technical textiles.

Performance of technical textile sector during COVID-19 pandemic

- Amid the COVID-19 pandemic, India emerged as one of the chief exporters of technical textile in the world.

- Apart from feeding its domestic needs with surgical masks, gears, and other protective equipment, India exported a large quantity of these items to other countries.

- During the COVID-19 pandemic, India emerged as one of the top countries in the world to export technical textile-based medical equipment and protective gear.

Conclusion:

The rise of India’s technical textile sector was well documented during the COVID-19 pandemic when India produced surplus medical and surgical protective gears based on technical textiles. It earned global praise by exporting a large amount of these necessary products globally. Technical textiles are in great demand globally due to their versatile applications, durability, and strength in different segments. Hence, India must push to expand its production capacity under ‘AAtmanirbhar Bharat Abhiyan’ in the process of becoming a $5 trillion economy by 2024.